What is ModFrame

ModFrame is a software tool made to support fast development and configuration of model based systems for process operation applications. ModFrame may be viewed as a development environment for model based process control applications. However, it may be used as a basis for many different computations which are to be performed cyclic. ModFrame consists of a set of components performing different tasks.

ModFrame is thus a set of software tools with the following purposes:

-

Defining computational algorithms for control of a process or for simulation purposes based on predefined algorithms and hierarchically organized control blocks.

-

Configuration of numerical process descriptions and process topologies by drawing process diagrams on a computer screen.

-

Configuring and parameterizing these models/algorithms.

-

Execution of on-line model based process supervision and control functionality.

-

Interaction and communication with existing control system and process I/O functionality via Apis Hive. Apis Hive is both an OPC server and has the possibility to communicate with other OPC server through its OPC client.

-

The component based structure ensures re-usability and flexibility.

Application structure

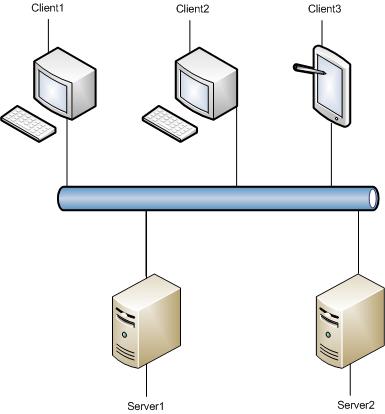

ModFrame consists of a server and a client which runs independently of each other. The client connects to a server and configures it, but it can be closed without affecting the server's computations.

Servers perform the actual computations, and several servers can run on different machines and share the computational load by passing data to each other through ApisHive's OPC mechanisms. Data from an external I/O system will also typically be retrieved from ApisHive.

The client, as opposed to the server, has an advanced user interface (UI), enabling the configuration of the server as well as displaying current computational results. Several clients can connect to a single server, and configure or view results simultaneously.

The basic UI is a graphical process representation, where each process unit or computational unit (real or conceptual/functional) is represented by a graphical icon in a process graphics picture. For a chemical process part, this graphic representation may look like a simplified process flow sheet with computational units attached (controllers, optimisers, soft sensors).

Dependencies

- ModFrame is a Java-application and the Java Runtime Environment (JRE) 1.6 must be installed on the computer running ModFrame.

- If ModFrame is to run in the ApisHive environment, the ApisJavaBee must be installed.

- The ModFrame installation kit runs currently only in Windows. If ModFrame is to be used on other platforms, please contact Prediktor for installation instructions. www.prediktor.no.

Installation

By double-clicking the ModFrame.msi file, the ModFrame application will be installed. Both the server and client software will be installed. It is currently not possible to only install the server or the client. After installation go to the All Programs->APIS->ModFrame where there will two items: ModFrame Client and ModFrame Server.

Choose the ModFrame Server and observe that the server window is displayed.

Choose the ModFrame Client and observe the client window is displayed. Connect to the server started in the previous steps.

See also: Classpath and JavaOptions.

Using ModFrame

Concepts

Server

Introduction

The server can either run stand-alone or as part of the ApisHive application through the ApisJavaBee-module. The ModFrame server will perform the actual computations and communicate with I/O systems for instance through the ApisHive framework. It runs independently of whether one or more clients are connected. It can be configured to load an application file and start performing computations when the it starts both as a stand-alone server and when it runs as a part of the ApisHive framework.

Stand-alone server

When the server runs as stand-alone, it can be started by selecting the following entry All Programs->Apis->ModFrame->ModFrame server.

Server settings

The server settings will be read from the serverstart.ini file in the ModFrame installation directory. This is a text file where one line can contain one setting. The default value column indicates the value of the setting if it is not present in the file.

| Server setting | Description | |

|---|---|---|

| Servername | The name of the ModFrame server. | ModFrameServer |

| StartFile | The application file to load when the ModFrame server starts. | |

| MaxClients | The maximum number of clients. If the value is negative the number of clients is unlimited. | Unlimited |

| maxConfigMode | The maximum number of clients that can be in configuration mode simultaneously. | 1 |

| StartOnLoad | The application will start running computations automatically when the ModFrame server is started. | False |

| WindowVisible | If false the server window will not visible. | True |

| ApplicationPath | The path to where the application files are stored. | The home directory of the user. |

| LibraryPath | The path to where library files are stored. | The home directory of the user. |

| StateFilesPath | The path to where the state files are stored. | The home directory of the user. |

| XMLEncoding | The encoding used on the (xml) application files. | UTF-8 |

| LoginManagement | If true, enables authentication when clients try to connect to the server. | False |

| SampleTime | The initial time interval [ms] between computations. | 1000 |

| RedirectStandardOut | If true, there will be a window in the server window displaying the standard out messages. | True |

| RedirectStandardErr | If true, there will be a window in the server window displaying the standard err messages. | True |

| InitialRMIPort | The port on which the RMI registry accepts requests. If the port is taken, the next port is attempted. | 1099 |

| RemoteObjectPort | The port number on which the remote object receives calls (if zero, an anonymous port is chosen). | 0 |

| ShutdownAction | The action which will be performed when the application is shut down. (None, Save) | None |

| TransactionLockTimeout | The time [ms] an external transaction can take before being timed out. (E.g. when a Tracker transaction is performed from a web page.) | 25000 |

Batch file

It is possible to create a batch file which starts the server with custom settings. Below is an example of the contents of a batch file. This must be altered to fit the installation. Using batch files it is possible to set all java options as well as the ini-file containing the elements described above.

| Batch file | Copy Code |

|---|---|

C:\\\Program Files\Java\jdk1.6.0_03\bin\javaw.exe -Xmx768m -XX:+UseConcMarkSweepGC -verbose:gc -Dswing.defaultlaf=javax.swing.plaf.metal.MetalLookAndFeel -Djava.security.policy=java.policy -classpath C:\\\Apis\ModFrame\ModFrame.jar;C:\\\Apis\ModFrame\xml.jar;C:\\\Apis\ModFrame\jtds-1.2.2.jar;C:\\\Apis\ModFrame\ClickAndTrace.jar; com.modframe.server.MFServer "C:\\\Apis\ModFrame\serverstart.ini" | |

Part of the ApisHive Framework

The ModFrame application can run inside the ApisHive process through the ApisJavaBee-module. In this case the settings described for the stand-alone server will be exposed as properties in the ApisJavaBee-module, and the class-path and java options are set in registry.

ApisJavaBee

This module will load a java-application. Items can be created and connected to ports in ModFrame.

Properties

| Property | Description | Default value | ||

|---|---|---|---|---|

| ExchangeRate | The exchange rate in milliseconds when retrieving values from external items | 0 (Turned off) | ||

| Run | States whether the ModFrame is performing computations. | False | ||

| JavaAppVisible | Specifies if the ModFrame server window is visible or not. (If ApisHive is run as a windows server, the window is always invisible.) | True. | ||

| JavaAppStartfile | The application file which will be opened when ApisHive is started. | |||

| ApplicationFilePath | The path to where the application files are stored. | The ApisHive config folder | ||

| LibraryFilePath | The path to where the library files are stored. | The ApisHive config folder | ||

| TimeStep | The computational time interval [ms] between the computations. | 1000 | ||

| Timer | The time interval [ms] of the timer trigging the computations. This interval is the real-time interval between computations, whereas TimeStep is the simulated time interval. If the system is to be run real-time these two properties should be equal. | 1000 | ||

| MaxItemBufferStrategy | Specifies the size of the item buffer. The item buffer will be used when a computation cycle has not finished within its time slot. A snapshot of the current item values will be put in the item buffer. When the computation cycle has finished it will read the item values from the buffer and performing computations with those values. This is useful when a sudden CPU load of the computer running ApisHive makes the computations take longer than anticipated. If the CPU load persists the item buffer will be filled to its maximum size, and warnings will be issued. If this situation is recurring either the timer interval should be increased or the CPU usage must be decreased.

| 20 | ||

| EventReportLevel | The level of the reported events from the java application. (E.g. if Warning is chosen, Warning and Alarm events will be reported, but the Information events will not.) |

Expert properties

| Property | Description | Default value |

|---|---|---|

| TimeReferenceItem | An item whose value will be used as a time reference for this module instead of the system time. This means that the sample time in ModFrame will vary depending on the value of this item. | |

| StartupJavaClass | The java class which contains the startup method (StartupMethod). The default value points to the correct ModFrame class, and should not be changed when using ModFrame. | com/modframe/server/MFServer |

| StartupJavaMethod | The static java method in the StartupJavaClass run when the module is started. The default value points to the correct ModFrame method, and should not be changed when using ModFrame. | main |

| NativeJavaClass | The java class which contains the defintion of the native C-functions. The default value points to the correct ModFrame class, and should not be changed when using ModFrame. | com/modframe/server/ApisConnector |

| SaveAction | The action to be performed when the application shutsdown (None, Save) | None |

| ItemWriteMasking | Set the quality level of items that will be written to the Java application from this module | Write all qualities |

| PersistedValToInitVal | Choose strategy for copying and persisting current value to the InitValue. | Never |

| PersistedStateDestination | The destination of the state files. If the destination is not specified the states will not be persisted. The destination can either be to a file or to items. If the destination is a file the StateFileFolder property must be set to a valid folder where the files will be stored. If the destination is Items the StateLoggers property must be set to valid logger(s) to log the state of the application in Apis Honeystore. | None |

| StateLoggers | The loggers which will log the state if PersistedStatesDestination is Items. | |

| AutoDeletePersistenceItems | If PersistedStateDestination is Items (or Both files and items) items will be created behind the scenes in which the states will be stored. An item of this type will be removed if the last persistence action did not include the state which corresponds to this certain item and this property is set to true. The reason why one might to turn off this option is to reduce the time spent on persisting the states. | |

| StateFileFolder | The folder in which the state files are stored. |

Items

There are different types of items in the ApisJavaBee. Scalar, Vector and Matrix items can be connected to ports in ModFrame.

Scalar

The Scalar item type represents a scalar value of boolean, string or double precision floating point value. The value type is controlled with the ItemType attribute. It can only be chosen when creating an item and not be altered later on. The InputValue attribute specifies if the value is an input value to ModFrame or not.

| ItemType | Port equivalent |

|---|---|

| Bool | Digital port |

| Double | Analog port |

| String | String port |

Vector

The Vector item type represents a vector/array value of boolean, string or double precision floating point value. The value type is controlled with the ItemType attribute. It can only be chosen when creating an item and not be altered later on. The InputValue attribute specifies if the value is an input value to ModFrame or not.

| ItemType | Port equivalent |

|---|---|

| Bool | N/A |

| Double | Analog vector port |

| String | String vector port |

Matrix

The Matrix item type represents a matrix value of boolean, string or double precision floating point value. The value type is controlled with the ItemType attribute. It can only be chosen when creating an item and not be altered later on. The InputValue attribute specifies if the value is an input value to ModFrame or not.

| ItemType | Port equivalent |

|---|---|

| Bool | N/A |

| Double | Analog matrix port |

| String | N/A |

StateFileItem

An item for setting the state file name. The folder which it will be stored in or read from is specified in the StateFileFolder property. The PersistedStateDestination property must also be set to File(s).

Attributes

| Attribute | Description |

|---|---|

| FileAccess | Decides whether the file specified in the item is in read, write or read/write mode. |

| TriggerOnChange | If true the state file will be read/written to when the item changes |

| IncludeStateFileFolder | If true the state file will be put in the StateFileFolder, otherwise it will be stored in the current directory |

| ForceStopBeforeRead | Will force the application to go to the STOPPED state before starting to load the state file. If this attribute is false, the application must be put in the STOPPED state manually. |

StateTriggerItem

An it for trigging state reading or writing.

| Attribute | Description |

|---|---|

| ReadStates | If true triggers reading of states, if false triggers writing. All files specified in the StateFileItems with the FileAccess set to Read will be read when this value is true and the ReadStates is true. If ReadStates is false all files specified in the StateFileItems with the FileAccess set to Write will be writtent o when this value is true. |

CommandItem

The command button can start and stop computations in ModFrame.

| Attribute | Description |

|---|---|

| CommandType | The type of command performed when the item's value is set to true. (Run/Stop) |

| Reset | Will perform a reset in the ModFrame at the next iteration after the command has been executed if true |

StatusItem

The status items show the current status of the server.

| Attribute | Description |

|---|---|

| StatusAsString | Displays the current status as a string instead of an integer |

Advanced

Class path

The class path is stored in the default value of the registry key:

HKEY_CLASSES_ROOT\Prediktor.ApisJava\CLASSPATH

| ModFrame may stop working if this value is altered. Do not change the value unless you know what you are doing! |

Java options

The java options are stored in the default value of the registry key:

HKEY_CLASSES_ROOT\Prediktor.ApisJava\JAVAOPTIONS

| Altering this value may cause ModFrame to stop working properly. |

| The -Xrs property should always be present as the absence of this value will force ModFrame to terminate when a user logs off. |

Application

A ModFrame application is the set of components residing in a ModFrame server at any given time. The application is hierarchical in that some components can contain other components. There will always be a single root parent component called the top application which is responsible for the computational algorithm. The application can be saved to and opened from files. The application files are stored on a particular folder on the server, and the clients can browse that folder and choose files from it. The application file location is set in the server settings. There are two file formats available (xml and mfz). The xml file format is a pure xml file and tend to become large. The mfz file format is a compressed version of the xml file, and is better suited for large applications.

It is possible to make the server open a particular application file automatically when the server starts up through the server settings.

Application states

It is possible to take snapshots of the current state of the application and store it to files (or Apis items). Even though the application files also contain snapshot information it also contains configuration information making the files large and relatively slow to open. As opposed to this the state files generally become small and very fast to open.

The state files contain what is needed for an application to reach the same state as it was in when the states were persisted. It depends largely on the component what is considered to be the states. In addition to the inner states of the components, the port values are persisted.

| A state file will only work and load the correct if the application has not changed since when the states were persisted. |

The location of the states files are controlled in the server settings.

Computational algorithm

The server will perform computations on a cyclic basis. In an application there must be a root parent called a top application. The top application is a ModFrame component that is a container. A container can contain child components. The child components can both be ModFrame components and views. By adding a ModFrame components that are containers to the top application, it is possible to create a component hierarchy.

The computational algorithm of the child ModFrame components is decided by each container. For the detailed computational algorithm see the documentation of the particular container. Even though it is up to the container to decide the computational algorithm, there are two distinct algorithms that will be common to most containers.

Parallel computations

When the computations are performed in parallel, that means that the container will iterate through its child component list twice. The first iteration will read all input ports and perform the actual computations. The next iteration will write the results to the output ports. This algorithm ensures that the computational results will be independent on the computational position of the child components. However it will also have that consequence that value will take longer to propagate through components connected serially. Let's say that we have three ModFrame components connected to each other in this way: component1's output is connected to component 2's input and component 3's input is connected to component 2's output. A change on component 1's input will take three computational iteration's to reach component 3's output.

Sequential computations

When the computations are performed sequentially, the container will only iterate through its child component list once. In that iteration each component will copy values to its input ports from the output ports of other components, read the input ports, perform computations and write to its output ports sequentially. The computational results of this algorithm are very dependent on the order of the child components. It's easier to make mistakes with this algorithm in the configuration phase, but it has the advantage of being able to propagate signals faster through connected components. The propagation can in this scenario only take one time step if the components are ordered correctly.

ModFrame component

A ModFrame component (MFC) is a software component performing one or more dedicated tasks. Examples of such tasks are: mathematical simulation of process equipment (pipes, tanks, heat exchangers), reading online data and performing computations on them, communicating with databases through JDBC.

A ModFrame component will have one or more property pages depending on the complexity of the component. The behavior of the component is influenced by changing these properties. ModFrame components interact with other ModFrame components through ports. The number of ports and the meaning of these ports vary from component to component, but generally ports are created and deleted by changing the properties of a component.

In the user interface the ModFrame component will be represented by an image, preferably indicating the task the component is performing.

Container

A container is a special ModFrame component which can contain other ModFrame components and views. The container will perform computations on its child components based on its computational algorithm. The container can expose ports of its child components making it possible to communicate with components in other containers. It is possible to group a set of components as a container and also ungroup a container.

In the user interface the container looks like an ordinary ModFrame component, but it can be expanded to edit the contents of the container.

Ports

The preferred way of exchanging data between ModFrame components is through ports. Ports can be connected to other ports and receive and or send information from/to those ports. There are different types of ports containing different types of data. There are two major types or ports: Unidirectional and bidirectional. In the unidirectional ports information will always flow in one direction. Whereas in bidirectional ports information will flow in both directions. The computational algorithms of the containers specifies and enforces the data exchange between the ports.

In the user interface the ports will reside inside of the image of a ModFrame component as a small movable square.

Unidirectional ports

The following table lists the available unidirectional ports in ModFrame proper. Extensions to ModFrame such as the Tracker modules may define additional ports. Unidirectional ports are either input or output ports and they can only be connected to the same port types of the opposite direction. (Inputs can only be connected to outputs, and vice versa.)

| Unidirectional port | Data type | Notes |

|---|---|---|

| Analog matrix | A matrix of double precision floating point values | The number of rows and columns of the matrix can be either static or changed depending on the connected port. |

Bidirectional ports

ProcessPorts.

Overview

The ModFrame client is the tool for configuring a ModFrame application. The client can be connected to one server at the time, but several clients can simultaneously be connected to the same server. The client displays the contents of the connected server graphically in the Configuration panel, as well as the component hierarchy in the Browser.

The Menu and the Tool bar is used for operations, as well as popup menus on the components in the configuration panel and browser. Messages (information, warning and alarms) are presented in the Log view.

Starting the client

After ModFrame has been installed the ModFrame client can be started by selecting All Programs->Apis->ModFrame->ModFrame client.

Batch file

It is possible to create a batch file which starts the client with custom settings. Below is an example of the contents of a batch file. This must be altered to fit the installation. Using batch files it is possible to set all java options. It is also possible to give a file name as a parameter containing settings for the client.

| Batch file | Copy Code |

|---|---|

C:\\\Program Files\Java\jdk1.6.0_03\bin\javaw.exe -Xmx500m -Dswing.defaultlaf=javax.swing.plaf.metal.MetalLookAndFeel -Djava.security.policy=java.policy -classpath C:\\\Apis\ModFrame\ModFrame.jar;C:\\\Apis\ModFrame\xml.jar;C:\\\Apis\ModFrame\ClickAndTrace.jar; com.modframe.client.MFClient "C:\\\Apis\ModFrame\clientsettings.ini"

| |

Client settings

The following settings can be applied to the client by adding them to the client settings file.

| Property | Description | Default value |

|---|---|---|

| ProductName | The name of the product | ModFrame |

| AutoConnect | If true the server set in the InitialConnectionServer connected automatically on startup. | |

| InitialConnectionServer | The server to connect to on start up. The format is rmi://ip-address/servername:port | |

| ServerReadInterval | The interval [ms] between reconnect attempts when the server connection is lost and the interval between history value updates. Cannot be less than 1000 ms | 1000 |

| HelpExec | The location of the help file. | current-directory/help |

| RemoteObjectPort | The RMI port. Use when the client/server are separeted by firewall. | Automatically obtained. |

User interface elements

Menu

The menu bar consists of menus performing different tasks on the client and server. Consider the tool bar for additional operations.

File

| File command | Shortcut key | Task |

|---|---|---|

| New | Ctrl+N | Creates a new application. |

| Open... | Ctrl+O | Open an existing application. |

| Save | Ctrl+S | Save the current application |

| Save as... | Save the current application a specific filename. | |

| Load states... | Load a states file. | |

| Save states... | Save the states file. | |

| Import connections... | Import port and I/O connections. | |

| Export connections... | Export port and I/O connections. | |

| Prints the configuration pane. | ||

| Preferences | Opens the preferences dialog. |

Application

| Application command | Shortcut key | Task |

|---|---|---|

| Create MFC... | Creates a new ModFrame component. |

Edit

| Edit command | Shortcut key | Task |

|---|---|---|

| Cut | Ctrl+X | Cuts the selected components. |

| Copy | Ctrl+C | Copies the selected components. |

| Paste | Ctrl+V | Pastes the cut or copied elements. |

| Delete | Delete | Deletes the selected components. |

View

| View command | Shortcut key | Task |

|---|---|---|

| Properties... | Opens the application view dialog. | |

| View definition... | Opens the view dialog. | |

| Layer definition... | Opens the layer dialog. | |

| Create plot... | Creates a historical plot tab. | |

| Grids... | Opens the grid dialog. |

Server

| View command | Shortcut key | Task |

|---|---|---|

| Properties... | Opens the application view dialog. | |

| View definition... | Opens the view dialog. | |

| Layer definition... | Opens the layer dialog. | |

| Create plot... | Creates a historical plot tab. | |

| Grids... | Opens the grid dialog. |

Tool bar

The tool bar consists of buttons and other UI elements performing tasks on the client and server. Consider the menu for additional operations.

| Name | Icon | Task |

|---|---|---|

| Port connection |   | Toggles whether it is possible to connect ports in the client. |

| Port move |   | Toggles whether it is possible to move the ports in the client. |

| Select view | N/A | Selects the active view. |

| Select layers |  | Selects the visible layers. |

| Zoom |   | Performs zooming in the configuration panel. |

| Log view |  | Hides/shows the log view. |

| Container bar |  | Hides/shows the container bar. |

| Help |  | Opens the user manual. |

Browser

The browser contains two (or three if a data source component is present in the application) tabs.

Application tab

The first tab displays the current application in hierarchical tree view. The root node of that tree represents the root ModFrame component (top application). The child components of that component is displayed on the next level and so on. In addition all the ports of a component is displayed as nodes in the tree. By right-clicking the component node a menu will be displayed. The application tab has the possibility to filter the components by name, and also ordering the components both by computational order as well as alphabetically.

Component tab

The component tab displays the available components which can be added to the application. The components are displayed in a tree view grouping common components by their functionality. There is a filter in the tab making it possible to filter the components by name.

History tab

The component tab presents available historic data sources in a tree view. The data sources will contain items which can be plotted or shown in a table.

Configuration panel

The configuration panel is where the ModFrame components and data views are displayed. The configuration of the components take place in this panel after components have been added to them. Each container can be made to display its child components in the configuration panels. A new tab will be created for each container when the container is made to display its child components.

Name

The name of the ModFrame component. This name will be visible below the ModFrame component in the ModFrame Client configuration panel.

| The name of a ModFrame component must be unique within the container it resides in. |

Log view

The log view displays messages from the server. The messages are displayed in a table. The first column displays a severity icon indicating information, warning or alarm. The second column displays the time of the message. The third column contains the source(s) (typically component name) of the message. The last column contains the actual message.

The log messages can be logged to files as well.

Container bar

The container bar will show the hierarchy position of a container making it easy to find parent and child controls of a container.

Server connection dialog

The server connection dialog makes it possible to connect to a server. The tables below describes the fields and buttons in the dialog.

| Field | Description |

|---|---|

| Computer | The name or IP address of the computer where the ModFrame server resides. The previous entries will be stored, and can be selected from the combo box. |

| Port | The IP port which the server communicates through (typical value is 1099-1200). By clicking the magnifying glass, it will be searched for a server from the port number and the 4 next ports. If no server is found the user can choose to search for a server in the next 5 ports etc. |

| Server | The name of the ModFrame server. Previous entries will be stored, and can be selected from the combo box. |

| User name | The user name. (Only applies if the server demands authentication.) |

| Password | The password for the user. (Only applies if the server demands authentication.) |

| Auto-update server list | If checked the server list will automatically update when the computer entry changes. |

| Button | Action |

|---|---|

| Connect | Connects to the server with the parameters entered in the fields. |

| Cancel | Cancels connection and close dialog. |

| Update server list | Gets the server list from the current computer entry. |

Add component dialog

The add component dialog makes it possible to create a ModFrame component to the connected server. The tables below describes the fields and buttons in the dialog.

| Field | Description |

|---|---|

| Type | A list of components that can be added to the server. |

| Name | The name of the component. |

| Button | Action |

|---|---|

| Ok | Creates the component with the parameters entered in the fields. |

| Cancel | Cancels connection and close dialog. |

Basics

Connecting to a server

Connection to the server can be obtained by clicking the Connect to server button in the tool bar. By filling in appropriate entries in the server connection dialog and clicking connect, the client will be connected.

| Error messages.... |

The client can be made to automatically connect to a specific server when it starts. This is obtained by creating a batch file for the client.

Configuration mode

When the client is in configuration mode it is possible to alter the configuration. When it is not in configuration mode, the user is only able to view the configuration and results.

The configuration mode is toggled by clicking the configuration mode button. Menus, buttons and other components may be disabled and enabled when client toggles between the configuration modes.

Add a ModFrame component

The user can either add a ModFrame component with the tool bar, menu or by dragging the component in to the configuration panel from the components tab. The last option enables the user to place the component in the panel initially, but the top application must be added by the two first options since the configuration panel does not exist.

Either one of the options will display the add component dialog. The user can select from the list and choose an appropriate name of the new component. If a component with the name supplied already exists in the container.

Add a container

A container can be added by either clicking the Add container button in the tool bar (the Add component dialog will be pre-selected with the AdaptableContainer), or by clicking the Add component button in the tool bar in which case the user must locate the container manually.

Edit properties

Properties of components are edited by right-clicking on the component and selecting Edit properties in the pop-up menu. A dialog box will generally contain a set of property pages, as well as a button row. The buttons are OK, Cancel and Apply.

The properties are updated in the server when OK or Apply are pushed. The OK button also closes the dialog box. Properties may depend on each other and depending on the complexity of the component, the user may have to click the Apply button several times when changing a set of properties. The property pages will be updated each time the user clicks Apply.(A component may for instance create or delete properties depending on the value of other properties.)

| Depending on the property, the value may be not validated when OK or Apply is clicked. If the user has chosen an illegal property value, a warning box will be displayed notifying the user of the error. The properties will not be actually written to the server component until the properties have been validated. |

Changing property values of a component will generally change the behavior of the component. Ports may for instance be created or removed when editing properties.

| Non-container components will display the property dialog box when double-clicked, where as the container components will expand itself when double-click. |

Consult the documentation for each component for more information on the properties available and their meanings.

Connect ModFrame components

ModFrame components communicate with each other through ports. Ports can connected in two ways:

Port connection dialog

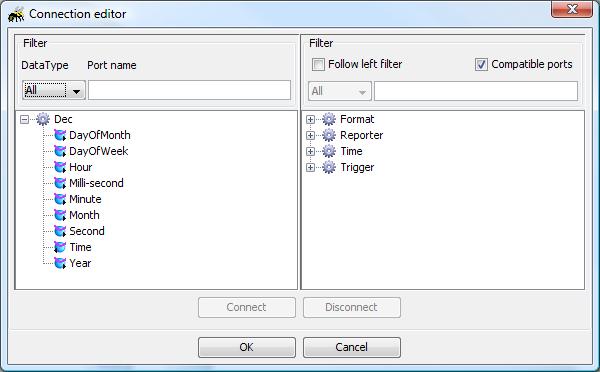

The port connection dialog is opened by right-clicking the component for which you want to connect ports and by choosing the Connect Ports menu entry. The port connection dialog contains two views. The first view contain filters and the ports of the component from which the dialog was opened, and the second view contains filters and all the other components in the container.

Filters

The left filters are a data type filter and a port name filter. By selecting entries in the DataType filter only ports that correspond to that data type will be shown. The port name filter works with wild cards so by setting the filter value to *tag* only ports with the word tag in them will be visible.

The right filters function in the same manner, but it is also possible to add extra limitations. If the Compatible ports check box is checked the right view will change when ports are clicked in the left view. Only ports that can be connected will be displayed in the right view. If the Follow left filter is checked the port name filter for the left filter is used.

Connection

Several connections can made in the dialog simultaneously, but the actual connections will only take place when the Ok button is clicked. The connection is made by either dragging and dropping the port from the left view to the right or by selecting the port in the left and right view and by clicking connect. Disconnect is performed by selecting the connected ports and clicking Disconnect.

Graphical port connection

The port connections can be made directly in the Configuration panel as well. To do this the Tool bar button must be clicked. Then the user must click either one of the ports to connect, a line will appear and be attached to the port. By clicking the other port the connection is finalized and the connection line will be drawn between the ports.

Add a data display

A data display for a port is created by right-clicking the port and selecting Create Data View menu item. A dialog is displayed with the following fields:

| Field | Description |

|---|---|

| MFC | The components which contains the port which the display is to show values. |

| Port | The name of the port whose value will be shown in the display. |

| View types | Selects the view which you want to display. |

| Add to | Add to existing view. (Only works for certain views.) |

Choose the data view and click ok.

Group components

It is possible to group several components in a container. The connections to components outside the selection will be maintained after the grouping. To group components select the components and right-click one of them and select Edit->Group components. Enter the desired name of the component and click Ok.

To ungroup the components right-click the container and choose Edit->Un-group, and the components will be ungrouped.

Exporting and importing port connections

Exporting connections

Port connections can be exported to a text file. This is useful when similar components are repeatedly added to a configuration. If the port names are similar it is fast to search and replace component and port names and import port connections instead of having to manually connect the ports.

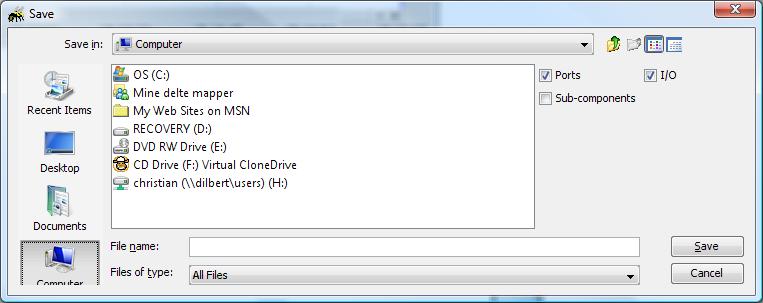

Port connections can be exported either by selecting File->Export connections... or by selecting the components to export port connections for and right-clicking one of the selected components and selecting Edit->Export connections. The first case will export connections for all components in the root container, where as the latter case only exports connections for the selected components.

The export connections dialog will be displayed:

The Ports check box indicate that port to port connections will be exported. The I/O check box indicates that port to Apis item or Apis item to port connections will be exported. The sub-components check box indicates that connections of components inside components that are containers will be exported.

| The connections file will be saved on the client. |

Importing connections

Port connections can be imported. This means that connections between ports can be made by importing a text file containing the connections.

To import connections select File->Import connections. A standard file selection dialog is displayed, and by selecting a file containing the connections, port connections are made.

File structure

The port connections file contains six tab separated columns. (There is no heading). The columns are shown below:

| Column 1 (Input) | Column 2 (Input) | Column 3 (Input) | Column 4 (Output) | Column 5 (Output) | Column 6 (Output) |

|---|---|---|---|---|---|

| Contains the complete component name of the component. The complete name consists of the all the container names down to the component. The component names are surrounded by a angular brackets. | The port or item name | True if Apis item, False if port | Contains the complete component name of the component. The complete name consists of the all the container names down to the component. The component names are surrounded by a angular brackets. | The port or item name | True if Apis item, False if port |

| Port connection file | Copy Code |

|---|---|

<asf><asf><Format> Time false <asf><asf><Time> CurrentTime false <asf><asf><Dec> Time false <asf><asf><Time> CurrentTime false | |

Exporting and importing components

Export

Components can be exported to file. This means that it is possible to reuse components created for one application in another. Both views and ModFrame components is exportable.

To export a set of components do the following:

- Select the components you wish to export.

- Right-click on one of them and select Export...

- A file dialog appears where you must give the file a name, click ok and the file is created.

| The file will be saved in the folder specified in the LibraryPath property (stand alone server) or LibraryFilePath (server runs in the ApisHive context) |

Import

To import an exported file, first make sure that the file is in the correct folder. Then right-click the container's background an choose Edit->Import Raw... or Edit->Import Default.

For non-Tracker components these two options are equal. For Tracker components Import Raw means that the tracker components keep the exported IDs. (MaterialDefintionID and so forth.) The safest bet is to use the Import Default option which sets all the IDs of the Tracker components to default values.

Controlling computations

Users can control the server's computations from the client. This is done from the tool bar.

Server parameters

The server parameters consist of the current server settings. Some of these settings are set from the serverstart.ini file (stand-alone server) or ApisJavaBee properties (server is run in the ApisHive context).

The server parameters can be viewed (and some of them changed) by selecting the top menu item Server->Server properties.

The following parameters are listed.

| Parameter | Description | Read-only |

|---|---|---|

| Timer interval | The time interval between computations | False |

| Logical sample time [s] | The time step | False |

| Server name | The name of the server currently connected | True |

| IP-address | The ip-address of the server currently connected | True |

| RMI port | The rmi port of the server currently connected | True |

| Application file | The name of the current application file | True |

| Application files path | The folder which the applications are stored in | True |

| State files path | The folder which the state files are stored in | True |

| Library files path | The folder which the library files are stored in | True |

| XML-encoding | The encoding of the application xml file. | True |

| Shutdown-action | Specifies an action at shutdown | True |

| Save-mode | Specifies the format of the application xml file. | False |

| Enable debug messages | If true debug messages will be displayed | False |

| Maximum clients | The maximum number of clients that can be connected to the server | True |

| Maximum clients concurrently in configuration mode | The maximum number of clients that can be in configuration mode simultaneously. | True |

| Start in run-mode | True if the server starts in run mode | True |

| Redirect standard error | Specifies if the standard error is redirected to the server window. | True |

| Redirect standard out | Specifies if the standard out is redirected to the server window. | True |

| Server window visible | If true the server window is visible | True |

| User input enabled on server | If true the user can interact with the server | True |

| User must log on to server | If true the user must log on when connecting to the server. | True |

| Remote Object port | The RMI port used. | True |

| Transaction lock timeout | False |

Views

A view is specified by coordinates in the configuration panel. After having defined a set of views, the user can select a view and navigate to it. This makes it faster and easier for users to navigate in the configuration panel.

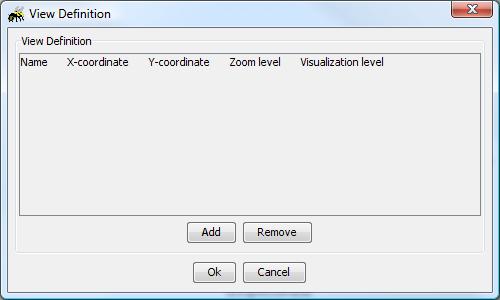

A view is defined by selecting View->View definition in the top menu. The following dialog is displayed:

By clicking the Add button a new view is defined. Give the view a sensible name, and fill in the other items as desired.

Layers

It is possible to define layers for the application. Components can be assigned to one specific layer, and from the client it is possible to choose which layers are visible. If a component belongs to a layer which isn't visible, the component will be hidden.

To create a layer select View->Layer definition. Each layer must have a unique level. After layers have been defined, views can include one or more layers. The user can select which layer is visible directly in the tool bar as well.

Modframe Components

Array operations

VectorAccumulator

Creates double vectors from a single double input value. There is a port which contains the current index where the double input value will be put. The vector will be accumulated until the AccumulateNewVector port becomes true. At this point a new vector will be created where the input values will be put. If the Vector Delay property is larger than 1 the older vectors will be shifted.

| The AccumulateNewVector signal must be true before the accumulating starts. |

When the WriteVector signal goes high the oldest accumulated vector will written to the output port. The vector will be removed from internal list of accumulated vectors. If a new WriteVector signal is sent before the AccumulateNewVector is true, the oldest vector value will be written, but now this vector will not be deleted and subsequent WriteVector signals will write that vector until an AccumulateNewVector signal has been issued.

The proper and most intuitive way of accumulating vectors will thus be to signal AccumlateNewVector as many times as there are supposed to be buffered vectors (as given by the Vector delay property) and then signal AccumlateNewVector and WriteVector every other time.

Properties

Name

The name of the ModFrame component. This name will be visible below the ModFrame component in the ModFrame Client configuration panel.

| The name of a ModFrame component must be unique within the container it resides in. |

Vector length

The length of the generated vectors

Vector delay

The number of vectors buffered. Each time the AccumulateNewVector signal is called the current vectors are shifted in the buffer. If the buffer is of equal length as this property, the oldest vector will be discarded.

Accumulation rules

Specifies when the input value is written to the accumulated vector.

The options are

- First value - The value will be accumulated when the index port value is changed.

- Last value - The value will be accumulated continuously (this means that the last value will be accumulated).

Initial element value

Specifies the value of the elements prior to being set. All elements not set by the index/value pair will maintain this value.

The options are:

- NaN - The initial value will be NaN (Not a number).

- 0.0 - The initial value will be 0.0.

Ports

| Port name | Description | Direction | Type |

|---|---|---|---|

| Value | The value to be inserted in the currently accumulating vector. | Input | Analog port |

| ValueIndex | The index where the value will be inserted in the currently accumulating vector. | Input | Analog port |

| AccumulateNewVector | Signals if a new vector will be created and starts to accumulate. The older vectors will be shifted in the buffer. | Input | Digital port |

| WriteVector | Signals if the oldest vector will be written to Vector port. | Input | Digital port |

| Vector | Contains an accumulated vector. | Input | Analog vector port |

Converters

Analog2ProcessPorts

Converts several analog inputs to one process port.

Properties

Parameters

Name

The name of the ModFrame component. This name will be visible below the ModFrame component in the ModFrame Client configuration panel.

| The name of a ModFrame component must be unique within the container it resides in. |

Vectors

DimConc

Decides the number of concentrations. Changing this will alter the number of concentration ports.

FlowPortVisible

If value is greater than zero, the analog flow port is visible.

DensityPortVisible

If value is greater than zero, the analog density port is visible.

EnthalpyPortVisible

If value is greater than zero, the analog enthalpy port is visible.

PressurePortVisible

If value is greater than zero, the analog pressure port is visible.

TempPortVisible

If value is greater than zero, the analog temp port is visible.

ConcPortsVisible

If value is greater than zero, the analog concentration ports are visible.

Ports

| Port name | Description | Direction | Type |

|---|---|---|---|

| Flow | The flow value to be inserted in the process port. | Input | Analog port |

| Density | The density value to be inserted in the process port. | Input | Analog port |

| Enthalpy | The enthalpy value to be inserted in the process port. | Input | Analog port |

| Pressure | The pressure value to be inserted in the process port. | Input | Analog port |

| Temperature | The temperature value to be inserted in the process port. | Input | Analog port |

| Conc 1 - N | The concentration value to be inserted in the process port. | Input | Analog port |

| ProcessPort | The resulting process port with values form the analog ports. | Output | Process port |

Decoder

The Decoder component is designed for value translation in the ModFrame application. On the basis of a set of defined translations (Code sets), the component will translate an input value provided on an input port and provide the result on an output port. The input and output may be analog, digital or string values.

Properties

The properties of this component are organized in multiple tabs. The separate tabs are described dedicated sub topics.

Properties

Name

The name of the ModFrame component. This name will be visible below the ModFrame component in the ModFrame Client configuration panel.

| The name of a ModFrame component must be unique within the container it resides in. |

Dimension

This property defines the dimension of the ports providing the input values and the ports providing the translated values. These ports may be vector or scalar.

Input type

This property defines the data type of the input port and the value to translate from.

Output type

This property defines the data type of the translated value and the port on which to provide the translated value.

Default output code

This property defines the default translation for values that appear on the input port but does not match the code sets.

Code set location

This property decides if the code sets is defined internally in the component or are provided on input ports to the component. The alternatives are:

- Internal. The code sets are defined through the code sets tab of the component.

- External. The code sets are provided on code set ports.

Code sets

This tab defines the valid translations when the Code set location property is Internal. The number of possible translations is unlimited.

| This parameter tab is based on the parameter matrix concept. Use the Add button to add a new row and the remove button to remove a selected row. The columns of the matrix are described below. |

InputCode

This column defines the values that can be translated

OutputCode

This column defines the translations of the values defined in the corresponding element of the InputCode column.

Ports

Input

This is the input port providing the value(s) for translation. The dimension of the port may be scalar or vector depending on the Dimension property.

Output

This is the output port providing the translated value(s). The dimension of the port may be scalar or vector depending on the Dimension property.

Activate

This is a digital port that can be used to activate/deactivate the component. If the component is deactivated, no translations will occur.

Code set ports

The code set ports appear when the Code set location is External.

- InputCodeSet. This is a vector port defining the values that can be translated.

- OutputCodeSet. This is a vector port defining the translations of the values defined on the InputCodeSet port.

NumToString

This component is designed to convert a numerical value to a string of a specific format.

Properties

Name

The name of the ModFrame component. This name will be visible below the ModFrame component in the ModFrame Client configuration panel.

| The name of a ModFrame component must be unique within the container it resides in. |

ReportEventLevel

All events with equal or higher severity will be reported.

Decimal format

This property defines the format of the converted string.

Ports

NumberValue

This is the port providing the numerical value to convert to a string.

StringValue

This port provides the string representation of the numerical value provided on th NumberValue port.

ProcessPort2Analog

Converts a process port to several analog ports representing the different parts of the porcess port (flow, pressure, density etc.)

Properties

Parameters

Name

The name of the ModFrame component. This name will be visible below the ModFrame component in the ModFrame Client configuration panel.

| The name of a ModFrame component must be unique within the container it resides in. |

Vectors

DimConc

Decides the number of concentrations. Changing this will alter the number of concentration ports.

FlowPortVisible

If value is greater than zero, the analog flow port is visible.

DensityPortVisible

If value is greater than zero, the analog density port is visible.

EnthalpyPortVisible

If value is greater than zero, the analog enthalpy port is visible.

PressurePortVisible

If value is greater than zero, the analog pressure port is visible.

TempPortVisible

If value is greater than zero, the analog temp port is visible.

ConcPortsVisible

If value is greater than zero, the analog concentration ports are visible.

Ports

| Port name | Description | Direction | Type |

|---|---|---|---|

| Flow | The flow value to be retrieved from the process port. | Output | Analog port |

| Density | The density value to be retrieved from the process port. | Output | Analog port |

| Enthalpy | The enthalpy value to be retrieved from the process port. | Output | Analog port |

| Pressure | The pressure value to be retrieved from the process port. | Output | Analog port |

| Temperature | The temperature value to be retrieved from the process port. | Output | Analog port |

| Conc 1 - N | The concentration value to be retrieved from the process port. | Output | Analog port |

| ProcessPort | The process port from which values are picked to be inserted in the analog ports. | Input | Process port |

StringAppend

This component concatenates a number of input strings to form a concatenated output string.

Properties

Name

The name of the ModFrame component. This name will be visible below the ModFrame component in the ModFrame Client configuration panel.

| The name of a ModFrame component must be unique within the container it resides in. |

ReportEventLevel

All events with equal or higher severity will be reported.

Delimiter

This property can be used to define a delimiter to separate the concatenated strings.

Number of strings to append

This property defines the number of strings to concatenate, and hence the number of input string ports.

Ports

Input string ports

The component contains a configurable number of string input ports providing the strings to concatenate.The name of these ports are String 1 - String N.

Appended string

This port provides the concatenated string.

Activate

This is a digital port that can be used to activate/deactivate the component. If the component is deactivated, no concatenation will occur.

StringParser

This component is designed to parse an input string for numerical values.

Properties

Name

The name of the ModFrame component. This name will be visible below the ModFrame component in the ModFrame Client configuration panel.

| The name of a ModFrame component must be unique within the container it resides in. |

ReportEventLevel

All events with equal or higher severity will be reported.

Maximum number of parsed values

This property defines the maximum number of numerical values to parse from the input string. If the input string contains more numerical values, these will be neglected.

Delimiter

This property defines the delimiter used to separate the numerical values in the input string

Decimal separator

This property defines the decimal separator used in the input string.

Result type

This property defines how to expose the result. The alternatives are:

- Scalar. The parsed values are exposed on scalar ports. The number of scalar ports is defined by the Maximum number of parsed values property.

- Vector. The parsed values are exposed on a vector port. The number of elements in the vector is defined by the Maximum number of parsed values property.

Ports

StringValue

This port provides the string to parse for numerical values.

Parsed value ports

The parsed values are either exposed on a string vector port named ParsedValues or N scalar string ports named ParsedValue1 to ParsedValueN.

Deprecated

SoftPlc

The SoftPlc component is deprecated. The blocks of the SoftPlc is ported to ModFrame components. The tables below contains the corresponding ModFrame component to a SoftPlc block.

Analog

| SoftPlc block | ModFrame component | Notes |

|---|---|---|

| ABS | AbsoluteValue | |

| ADD | Sum | |

| ANADELAY | SignalDelay | The new component delays several input types. |

| CEIL | Ceiling | |

| CONV | N/A | |

| COS | Cosine | |

| COUNTER | PulseCounter | Used together with Compare. |

| COUNTER2 | PulseCounter | |

| DERIV | TimeDerivation | |

| DIV | Division | |

| EXP | Exponential | |

| FLOOR | Floor | |

| GAIN | N/A | Use Multiplication instead. |

| HOLD | TimeStepDelay | The new component delays several input types. |

| INC | Increment | |

| INTGR | TimeIntegral | |

| LFILT | LowpassFilter | |

| LIMIT | Limit | |

| LINMOD | LinearModel | |

| LOG | Logarithm | |

| MAX | Maximum | |

| MEAN | Mean | |

| MEDIAN | N/A | |

| MIN | Minimum | |

| MULT | Multiplication | |

| NUM2STR | ||

| PID | See Control toolbox. | |

| POWN | Power | |

| RANDOM | Random | |

| RAMPUPDN | N/A | |

| ROUND | Round | |

| SAMPHOLD | Sampling | The new component handles several input types. |

| SELIN | DigitalMultiplexer | The new component handles several input types. |

| SELINN | Multiplexer | The new component handles several input types. |

| SELPAR | DigitalMultiplexer | No need for parameter/property. |

| SELPARIN | DigitalMultiplexer | No need for parameter/property. |

| SIN | Sine | |

| SQRT | SquareRoot | |

| STD | Standard Deviation | |

| SUB | Subtraction | |

| TAN | Tangent | |

| TIMESTEP | SampleTime | |

| YPOWX | Power |

Digital

| SoftPlc block | ModFrame component | Notes |

|---|---|---|

| AND | AND | |

| BITAND | BitwiseAnd | |

| CMPRH | Compare | Tests both for low and high limits. |

| CMPRL | Compare | Tests both for low and high limits. |

| CODECMPR2 | N/A | |

| CODECMPR3 | N/A | |

| COMPIN | Compare | |

| COMPINEQ | Equal | |

| DIGDELAY | SignalDelay | Select Digital as SignalType. |

| DIGSELINN | Multiplexer | Select Digital as SignalType. |

| DLATCH | Sampling | Select Digital as SignalType. |

| INV | Invert | |

| MONO | LastingPulse | |

| OR | OR | |

| OSC | SquarePulse | |

| PULSEDEL | PulseDelay | The PULSEDEL delayed for one time step less than it should. |

| RS | RSFlipFlop | |

| SAMPLE | Sampling | Sample Trigger must be High and SignalType must be Analog. |

| SNAPEVENT | Må lages | |

| SWITCH | DigitalMultiplexer | |

| TIMROFF | PulseLowDelay | |

| TIMRON | PulseHighDelay | |

| XOR | XOR |

Linear Algebra

| SoftPlc block | ModFrame component | Notes |

|---|---|---|

| ADD | Sum | |

| APPEND | Augment | The new component is more complicated, but can be used as the APPEND block. |

| COLUMN | ColumnsSelection | |

| COLUMNDIM | Dimension | |

| DELAY | TimeDelay | |

| DET | Determinant | |

| DIFF | N/A | Can obtain the same functionality with TimeStepDelay and Subtraction |

| EIG | Eigenvalues | |

| ELEM | ElementsSelection | |

| ELEMCOUNT | Dimension | |

| ELEMIN | ElementsSelection | |

| ELEMSET | SetElements | |

| IDENTITY | Identity | |

| IDENTITYSC | Identity | |

| INSROW | InsertRows | |

| INVERSE | Inverse | |

| MULT | Multiplication | |

| NORM1 | Norm | |

| NORM2 | Norm | |

| NORMF | Norm | |

| NORMINF | Norm | |

| NULLSC | Null | |

| RANDOM | Random | |

| RANK | Rank | |

| RMROW | RowsRemove | |

| ROW | RowsSelection | |

| ROWDIM | Dimension | |

| SAMPHOLD | Sampling | |

| SCALARMULT | ScalarMultiplication | |

| SELIN | DigitalMultiplexer | |

| SELINN | Multiplexer | |

| SUB | Subtraction | |

| SVD | SingularValueDecomposition | |

| SVDU | SingularValueDecomposition | |

| SVDV | SingularValueDecomposition | |

| TRANSP | Transpose | |

| VEC2VEC | N/A |

Math

Scalar

Arithmetics

Division

Divides the dividend input by the divisor input. (c = a/b)

Properties

Name

The name of the ModFrame component. This name will be visible below the ModFrame component in the ModFrame Client configuration panel.

| The name of a ModFrame component must be unique within the container it resides in. |

Divide by zero action

Specifies the output value if the divisor is zero. The alternatives are:

- Zero - The output becomes zero

- NaN - The output becomes NaN (not a number).

- Infinity - The value is either positive or negative infinity, depending on the dividend.

- PortValue - The value is retrieved from a port.

Ports

| Port name | Description | Direction | Type |

|---|---|---|---|

| Dividend | Contains the value above the fraction bar. | Input | Analog port |

| Divisor | Contains the arguments which will be summed. | Input | Analog port |

| Result | Contains the division value. | Output | Analog port |

Multiplication

Multiplies the inputs and writes the result to the output.

Properties

Name

The name of the ModFrame component. This name will be visible below the ModFrame component in the ModFrame Client configuration panel.

| The name of a ModFrame component must be unique within the container it resides in. |

Inputs

The number of inputs which will be multiplied.

Ports

The number of input ports will vary depending on the Inputs property.

| Port name | Description | Direction | Type |

|---|---|---|---|

| Argument 1 to N | Contains the arguments which will be multiplied. | Input | Analog port |

| Result | Contains the multiplied value of the inputs. | Output | Analog port |

Subtraction

Computes the difference between the minuend with the subtrahend. Example: c − b = a. c is the minuend, b is the subtrahend and a is the difference.

Properties

Name

The name of the ModFrame component. This name will be visible below the ModFrame component in the ModFrame Client configuration panel.

| The name of a ModFrame component must be unique within the container it resides in. |

Ports

| Port name | Description | Direction | Type |

|---|---|---|---|

| Minuend | Contains the minuend value. (The minuend is c in the equation: c - b = a) | Input | Analog port |

| Subtrahend | Contains the subtrahend value. (The subtrahend is b in the equation: c - b = a) | Input | Analog port |

| Difference | Contains the difference between the minuend and the subtrahend. | Output | Analog port |

Sum

This component sums two or more analog inputs and writes the sum to an analog output.

Properties

Name

The name of the ModFrame component. This name will be visible below the ModFrame component in the ModFrame Client configuration panel.

| The name of a ModFrame component must be unique within the container it resides in. |

Inputs

The number of inputs which will be summed.

Ports

The number of input ports will vary depending on the Inputs property.

| Port name | Description | Direction | Type |

|---|---|---|---|

| Argument 1 to N | Contains the arguments which will be summed. | Input | Analog port |

| Result | Contains the summed value of the inputs. | Output | Analog port |

Calculus

SampleTime

Exposes the current sample time in a port.

Properties

Name

The name of the ModFrame component. This name will be visible below the ModFrame component in the ModFrame Client configuration panel.

| The name of a ModFrame component must be unique within the container it resides in. |

Ports

| Port name | Description | Direction | Type |

|---|---|---|---|

| Sample time | Contains the current sample time. | Output | Analog port |

TimeDerivation

The time derivation of the input value. The time derivation is found by subtracting the current input value with the input value of the previous time step and dividing the result by the sample time.

Properties

Name

The name of the ModFrame component. This name will be visible below the ModFrame component in the ModFrame Client configuration panel.

| The name of a ModFrame component must be unique within the container it resides in. |

Ports

| Port name | Description | Direction | Type |

|---|---|---|---|

| Input value | Contains the value for which the time derivation value is found. | Input | Analog port |

| Result | Contains the value of the time derivation. | Output | Analog port |

TimeIntegral

The time integral of the input value. When the reset port is true, the integral value will be reset to zero. If the hold port is true the integration is paused.

Properties

Name

The name of the ModFrame component. This name will be visible below the ModFrame component in the ModFrame Client configuration panel.

| The name of a ModFrame component must be unique within the container it resides in. |

Gain

The value gain property is multiplied with the current integral value. It is possible to expose this property as a value.

Ports

| Port name | Description | Direction | Type |

|---|---|---|---|

| Input value | Contains the value which will be time integrated. | Input | Analog port |

| Reset | If the value is true the integrated value (Result) will be reset to zero. | Input | Digital port |

| Hold | If the value is true the integrated value (Result) will be held constant. | Input | Digital port |

| Result | Contains the value of the time integration. | Output | Analog port |

Statistics

Mean

Finds the mean of the input signal. A window size can be applied in which case older input values have less significance on the mean value (i.e. a forgetting factor).

Properties

Name

The name of the ModFrame component. This name will be visible below the ModFrame component in the ModFrame Client configuration panel.

| The name of a ModFrame component must be unique within the container it resides in. |

Window size

The window size specifies the weight of the previous values compared to the new value. If the current time step has exceeded the window size, previous mean value is given the weight of the (Window size - 1)/Window size whereas the new value is given the weight of 1/(Window size). This implies that the new values are given more weight than the older values. If no weighing is to take place set the window size to a very large number.

Ports

| Port name | Description | Direction | Type |

|---|---|---|---|

| Input value | Contains the value which for which the mean value will computed. | Input | Analog port |

| Reset | If the value is true the mean value (Result) will be reset to zero. | Input | Digital port |

| Hold | If the value is true the mean value (Result) will be held constant. | Input | Digital port |

| Result | Contains the current mean value. | Output | Analog port |

Standard Deviation

Finds the mean and standard devation of the input signal. A window size can be applied in which case older input values have less significance on the mean and standard deviation (i.e. a forgetting factor).

Properties

Name

The name of the ModFrame component. This name will be visible below the ModFrame component in the ModFrame Client configuration panel.

| The name of a ModFrame component must be unique within the container it resides in. |

Window size

The window size specifies the weight of the previous values compared to the new value. If the current time step has exceeded the window size, previous mean and standard deviation values are given the weight of the (Window size - 1)/Window size whereas the new value is given the weight of 1/(Window size). This implies that the new values are given more weight than the older values. If no weighing is to take place set the window size to a very large number.

Ports

| Port name | Description | Direction | Type |

|---|---|---|---|

| Input value | Contains the value which for which the mean and standard deviation will computed. | Input | Analog port |

| Reset | If the value is true the mean and standard deviation will be reset to zero. | Input | Digital port |

| Hold | If the value is true the mean and standard deviation will be held constant. | Input | Digital port |

| Mean | Contains the current mean value. | Output | Analog port |

| Standard deviation | Contains the current standard deviation. | Output | Analog port |

Trigonometrics

Acosine

Finds the arc-cosine value of the input. The output is given in radians.

Properties

Name

The name of the ModFrame component. This name will be visible below the ModFrame component in the ModFrame Client configuration panel.

| The name of a ModFrame component must be unique within the container it resides in. |

Ports

| Port name | Description | Direction | Type |

|---|---|---|---|

| Input value | Contains the value for which the arc cosine value will be found. | Input | Analog port |

| Result | Contains the arc cosine value in radians of the input. | Output | Analog port |

Asine

Finds the arc-sine value of the input. The output is given in radians.

Properties

Name

The name of the ModFrame component. This name will be visible below the ModFrame component in the ModFrame Client configuration panel.

| The name of a ModFrame component must be unique within the container it resides in. |

Ports

| Port name | Description | Direction | Type |

|---|---|---|---|

| Input value | Contains the value for which the arc sine value will be found. | Input | Analog port |

| Result | Contains the arc sine value in radians of the input. | Output | Analog port |

Atangent

Finds the arc-tangent value of the input. The output is given in radians.

Properties

Name

The name of the ModFrame component. This name will be visible below the ModFrame component in the ModFrame Client configuration panel.

| The name of a ModFrame component must be unique within the container it resides in. |

Ports

| Port name | Description | Direction | Type |

|---|---|---|---|

| Input value | Contains the value for which the arc tangent value will be found. | Input | Analog port |

| Result | Contains the arc tangent value in radians of the input. | Output | Analog port |

Cosine

Finds the cosine value of the input. The input is given in radians.

Browser path: Math\Scalar\Trigonometric\Cosine

Properties

Name

The name of the ModFrame component. This name will be visible below the ModFrame component in the ModFrame Client configuration panel.

| The name of a ModFrame component must be unique within the container it resides in. |

Ports

| Port name | Description | Direction | Type |

|---|---|---|---|

| Input value | Contains the value in radians for which the cosine value will be found. | Input | Analog port |

| Result | Contains the cosine value of the input. | Output | Analog port |

Sine

Finds the sine value of the input. The input is given in radians.

Properties

Name

The name of the ModFrame component. This name will be visible below the ModFrame component in the ModFrame Client configuration panel.

| The name of a ModFrame component must be unique within the container it resides in. |

Ports

| Port name | Description | Direction | Type |

|---|---|---|---|

| Input value | Contains the value in radians for which the sine value will be found. | Input | Analog port |

| Result | Contains the sine value of the input. | Output | Analog port |

Tangent

Finds the tangent value of the input. The input is given in radians.

Properties

Name

The name of the ModFrame component. This name will be visible below the ModFrame component in the ModFrame Client configuration panel.

| The name of a ModFrame component must be unique within the container it resides in. |

Ports

| Port name | Description | Direction | Type |

|---|---|---|---|

| Input value | Contains the value in radians for which the tangent value will be found. | Input | Analog port |

| Result | Contains the tangent value of the input. | Output | Analog port |

AbsoluteValue

This component takes the absolute value of the analog input and writes it to the output.

Properties

Name

The name of the ModFrame component. This name will be visible below the ModFrame component in the ModFrame Client configuration panel.

| The name of a ModFrame component must be unique within the container it resides in. |

Ports

| Port name | Description | Direction | Type |

|---|---|---|---|

| Input value | Contains the value for which the absolute value will be found. | Input | Analog port |

| Result | Contains the absolute value of the input. | Output | Analog port |

Ceiling

Finds the smallest integer not less than x, or, formally

Properties

Name

The name of the ModFrame component. This name will be visible below the ModFrame component in the ModFrame Client configuration panel.

| The name of a ModFrame component must be unique within the container it resides in. |

Ports

| Port name | Description | Direction | Type |

|---|---|---|---|

| Input value | Contains the value for which the ceiling value will be found. | Input | Analog port |

| Result | Contains the ceiling value of the input. | Output | Analog port |

Exponential

The input value is run through the exponential function (y = e x).

Properties

Name

The name of the ModFrame component. This name will be visible below the ModFrame component in the ModFrame Client configuration panel.

| The name of a ModFrame component must be unique within the container it resides in. |

Ports

| Port name | Description | Direction | Type |

|---|---|---|---|

| Input value | Contains the value for which the expontial value will be found. | Input | Analog port |

| Result | Contains the expontial value of the input. | Output | Analog port |

Floor

Finds the largest integer less than or equal to x. Formally, for all real numbers x,

Properties

Name

The name of the ModFrame component. This name will be visible below the ModFrame component in the ModFrame Client configuration panel.

| The name of a ModFrame component must be unique within the container it resides in. |

Ports

| Port name | Description | Direction | Type |

|---|---|---|---|

| Input value | Contains the value for which the floor value will be found. | Input | Analog port |